About Us

Our journey and Vision

Company History

Driven by a keen eye for detail and the desire to deliver quality craftsmanship, Michael Vermouth founded Newfound Woodworks in 1984 producing intricately detailed cabinetry, fine furniture, custom doors and windows to high-end New England home builders. Michael’s passion led him to construct several cedar strip canoes for himself: he was hooked. Seeing the need to fill a market niche, Michael redirected the company’s full efforts into building high quality canoe kits and providing instructional manuals so people could build their own canoes with high quality materials. Later, he expanded into kits for kayaks and rowboats as well. Michael’s attention to detail brought him many awards of excellence, solidifying forever his position as a highly sought after fine craftsman.

"I started the Newfound Woodworks in October 1984 as a woodworking/cabinet shop. I manufactured custom doors, windows, cabinets, and furniture for about three years. When I found a cedar strip boatbuilding book and built two different canoes by lofting the offsets in the book onto particleboard. I became fascinated with this process because the boats were lightweight, strong, reasonably maintenance-free, and incredibly beautiful.

I began producing cedar strips at the request of others who wanted to build canoes. Soon I acquired epoxy, fiberglass, ash for gunwales, and decided that maybe we could supply 'kits' to those who wanted to build their own boat but didn't have all the millwork equipment necessary to produce quality strips, gunwales, decks, stems, etc.

I went to boat shows, and woodworking festivals produced catalogs and a website to market the kits. I hired several people, taught them how to build the boats, and ended up with several canoes, kayaks and rowing boats for display and shows.

We came up with the idea of an annual gathering of customers who had built their own boats, called "The Newfound Rendezvous." The Rendezvous was held every September on Lake Winnipesaukee and, most recently, on Newfound Lake from 1997 to 2007. This was a chance for both builders and anyone new to this to see our boats, ask questions, check out new designs, and see what others had accomplished.

This has been a very rewarding occupation, helping others achieve their dream of building a functional work of art. It has been my passion and my life; I can't think of anything else I would rather have done with my last thirty years."

Michael Vermouth

The Passion Continues On...

Meet The New Team

As a fine artisan of high quality custom woodwork, Michael recognized and regarded Alan Mann, of Alan Mann Construction LLC, as a builder of high quality custom homes for 40 years. This is what led to their long-standing business and personal relationship. Michael trusted Alan due to his own high standards, excellent quality craftsmanship and abilities that led Michael to commission Alan to remodel the Newfound Woodworks manufacturing facility in 1984 so he could accommodate cedar strip boat construction and kit manufacturing.

Michael and Alan knew each other well. Over the years, Michael would consult with Alan about numerous wood projects, and the two grew closer in friendship, riding motorcycles and snowmobiles together for many years.

Alan is a successful business owner and artisan in his own right within the custom home building industry. Highly sought after for his attention to detail, Alan has an outstanding reputation in fine woodworking and building custom homes, including log and post & beam homes, throughout the White Mountains and Lakes Regions of New Hampshire.

Rose Woodyard knew Michael for many years as well. She grew up and worked in the custom home and commercial building industry with her father owning a construction company himself. She is also a third generation artist, and owned her own business, and to this day creates and teaches her craft in various mediums including: metal & wood. Rose enjoys over 40 years of experience as a Custom Bench Fine Jeweler and is a three-time award winner in the fine jewelry industry in Nebraska before relocating to New Hampshire seventeen years ago, and is still sought after for her beautiful and unique fine jewelry creations and designs.

Like Michael, Rose and Alan are master craftsmen. Together they have been winning awards starting with the very first boat they built and winning every year since, showcasing their boatbuilding skills and creative one-of-a-kind intricate patterns and exquisite finishes. Both are instructors, teaching boatbuilding and fiberglassing at boatbuilding classes, seminars and workshops.

“With the untimely passing of our good friend Michael, the opportunity presented itself for us to carry out our close friend’s legacy of outstanding craftsmanship and workmanship, with a timeless rich heritage of quality that will be remembered and continued. We are dedicated to continue providing top quality materials, high quality craftsmanship and unsurpassed customer service.”

“We are excited to continue Michael’s rich heritage and carry on the passion! We look forward to the next 38 years, providing the finest high quality cedar strip canoe, kayak and rowboat kits available! We look forward to working with you for your next cedar strip boat project!”

Rose Woodyard & Alan Mann

About Our Shop

We at the Newfound Woodworks are dedicated to providing the highest quality materials to make what we consider to be the most beautiful boat designs available. We prefer strip building, so even though we now produce stitch and glue plywood kayaks, we really like our Hybrid construction method.

Your purchase of our products is only the beginning of our relationship. We have produced two videos in DVD format to provide a wealth of information. We are happy to answer questions by e-mail and telephone. Since we also build boats, we know how to get you through the process.

Our goal is to help you achieve a successful boat building endeavor no matter which construction method you choose.

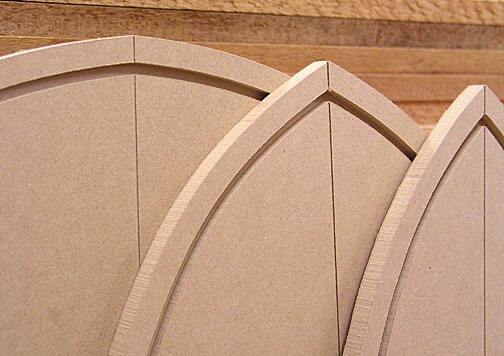

Strip-build, cedar-strip, cedar strip/epoxy, or wood strip all refer to the same technique for building a boat. This method lends itself readily to canoes, kayaks, and small rowing boats. Thin strips of wood are edge-glued together around temporary forms, faired, and covered inside and out with epoxy and fiberglass cloth.

Strip-build, cedar-strip, cedar strip/epoxy, or wood strip all refer to the same technique for building a boat. This method lends itself readily to canoes, kayaks, and small rowing boats. Thin strips of wood are edge-glued together around temporary forms, faired, and covered inside and out with epoxy and fiberglass cloth. These are really wood cored fiberglass boats; the epoxy and fiberglass are the strength and protection, and the wood core is the shape and beauty. Cedar strip/epoxy boats require much less maintenance than traditional wood boats; a new coat of varnish for UV protection every couple of years will keep your canoe or kayak looking like new.

These are really wood cored fiberglass boats; the epoxy and fiberglass are the strength and protection, and the wood core is the shape and beauty. Cedar strip/epoxy boats require much less maintenance than traditional wood boats; a new coat of varnish for UV protection every couple of years will keep your canoe or kayak looking like new.